HISTORIC STEEL WINDOWS REPAIR, RESTORATION & WEATHERIZATION

Why would you repair a metal window? Let's ask the experts:

Any window that can be repaired should be repaired.

"The big issue... with classic steel casement windows is energy efficiency. While steel is not a good insulator of heat or cold, glass is far worse. [Heat loss from windows is about the same] regardless of what material the window sash is made of or the type of glass. Air infiltration is the primary culprit...."

Repair & Restoration

What To Do?

There is not a single and simple answer, because the repair depends on:

- what parts of the window are deteriorated and how badly, and

- what the goal is for the windows.

Repair goals can range from minimal to extensive. In fact, the less, the better!

- Preservation. Original windows are repaired only enough to prevent further deterioration. This minimum repair is sufficient to preserve original windows into the future. By preserving the windows, they are saved for eventual rehabilitation.

- Energy efficiency. Historic windows can be weather-tight and energy efficient. If this is the main goal for the windows, then minimum repair may be enough.

-

Rehabilitation. In the Secretary of Interior (SOI) Standards for Rehabilitation, original windows and materials are preserved as much as possible.

- Windows are repaired to the least extent possible to make them functional and to preserve them from deterioration.

- Limited replacement of damaged material is allowed.

- Windows are weatherized.

- Rehabilitation of windows is explained in the SOI Guidelines for Rehabilitation.

-

Restoration. This is the highest standard. Windows are entirely restored toward their original condition.

- Window glass is removed, reset, and reglazed.

- Finishes are removed and replaced.

- Hardware is repaired or replaced.

- All damaged metal is repaired, and if necessary replaced with the same kind of metal, if possible. Major repair might be required when metal is badly corroded or even bent. Windows are weatherized.

- Total restoration is more than is required or expected by the SOI Rehabilitation Standards. However, complete restoration is the ultimate historic preservation, if that is a goal.

Have a plan

The How to Do It section shows what things can be done, from minimal to full restoration. Know what the goal is, then plan just the repair needed to get there.

Don't overdo it.

What do you need to know?

You need to know only how to do the repairs the windows need. Nothing more. What you need depends on the goal and the plan.

How To Do It?

What needs to be done for steel windows falls into three categories.

- Weatherization

- Routine Maintenance and Specific Repairs

- Major Repairs

The main thing is knowing what to do and how to do it.

The two courses of action...

- Do-It-Yourself

- Hire a contractor

DIY Steel Window Repair & Restoration

Repairs to steel windows usually are not complicated.

Many repairs require only simple skills and common tools. A Do-It-Yourself owner can save money doing some or all of the repairs. Many historic homeowners are more familiar with working with wood than with metal. Nonetheless, with knowledge about steel windows, the DIY owner can do many repairs.

Major repairs, however, are more likely to require a window repair professional with more metalworking capacity than owners have.

The first step is to figure out the condition of the windows. Remove surface dirt and grease and scrape away loose and flaking paint. Only then can any metal deterioration be assessed.

Surface imperfections do not necessarily indicate actual deterioration of the window material. Even if there is paint build up, cracked or broken glass, missing hardware, and some evidence of rust, the steel windows still are not likely to be seriously deteriorated. What looks like a badly deteriorated window may just be a window that needs some deferred maintenance.

DIY Information in Three Parts

- Guidebooks. Comprehensive information about repairing steel windows. They are a guide to complete restoration of windows. But, one can use only the portions that provide information about the particular work that is needed.

Restoration. Most problems that owners have with window weatherization and deterioration can be solved without the total restoration of the windows that is explained in the Guidebooks. Most owners will not want to do such extensive work on their windows, and usually it is not necessary. Nonetheless, complete restoration is the ultimate historic preservation, if that is a goal. - Specific Repairs. Information and demonstrations on how to repair specific problems. The solutions to specific problems are the same as in complete restoration.

- Weatherization. Weatherization is the solution to the usual problems with steel windows.

Guidebooks

A good overview of preservation of historic steel casement windows is City of Phoenix, Steel Casement Window Repairs.

The guiding reference on historic steel windows is U. S. Secretary of the Interior, National Park Service, Preservation Brief 13, "The Repair and Thermal Upgrading of Historic Steel Windows" (Sharon C. Park, AIA).

Specific Window Repairs

Steel windows, like anything else, require maintenance and occasional repair to remain in top working condition. Routine maintenance includes

- cleaning,

- oiling moving parts,

- scraping off patches of peeling paint and rust and spot repainting, and

- periodically repainting the windows as needed, usually when the house is repainted.

For repair and weatherization of historic wood windows, see the article on Historic Window Repair and Rehabilitation

Specific Repairs

Repair

of steel windows differs in important ways from the repair of wood

windows. Materials made specifically for steel windows are needed, as

noted below.

Paint |

|

Paint poses two problems.

- Too little. Where paint starts to flake off, exposed metal can rust.

- Too much. Paint build up can keep windows from working properly.

Loose paint and light rust can be scraped or sanded off readily. A wire brush is useful, or even an electric drill with a wire brush.

Heavy paint build-up between the movable sash and the fixed window frame can prevent a window from closing tightly.

- Scrape away the excess paint until the sash fits snuggly in the frame and the window can be closed and latched.

- If scraping is not sufficient, chemical stripper may be necessary.

- NEVER USE HEAT. Intense heat risks breaking glass and distorting the metal.

Removing all paint from a window usually is not necessary. Any existing paint that still is tightly bonded to the metal still is good. However, full restoration of a steel window would strip off all paint and start fresh.

If any bare metal gets exposed, it needs to be painted immediately with a rust-inhibiting primer. NOTE: a primer especially for metal is needed, and the primer and the finish paint need to be chemically compatible. This means from the same manufacturer.

Other repairs need to be addressed before final painting.

Unsticking Windows |

|

Windows may not open for a variety of reasons, although the principal problem usually is that they are painted shut. First, be sure the window is unlocked. The paint seal will have to be broken. Work a putty knife or a utility knife along the edges of the movable sash until it breaks free. The paint seal could be inside, outside, or both.

Another common problem is that a casement sash is not sitting squarely in the window frame. The problem most likely is the hinges. Often, just tightening the hinge screws will pull the sash back into alignment with the frame.

If paint is not the problem, it may be a frozen crank mechanism (see below).

Replacing Glass |

|

Replacing Glass

Replacing cracked or broken glass in steel windows differs in details from replacement in wood windows. See This Old House as a reference.

Cutting Glass: This Old House shows how to cut glass to the right size.

Reglazing |

|

Loose or missing glazing can allow air infiltration, and it looks bad. Any loose glazing can be chipped off, the surface cleaned with a wire brush, and reglazed. The This Old House web site includes how to reglaze.

NOTE: a glazing compound specifically made for metal windows is needed, such as DAP 1012 (readily available). (Wood window putty won't last on steel.)

NOTE: a glazing compound specifically made for metal windows is needed, such as DAP 1012 (readily available). (Wood window putty won't last on steel.)

While the following demonstrations of glazing techniques are for wood windows, they are essentially the same as for steel windows.

- How to Repair Window Glazing: An excellent VIDEO demonstration of the process.

- Glazing can be done with the window sash in place. It is not necessary to remove the sash. How to Glaze a Window Pane VIDEO

- John Leeke, Window Sash Glazing VIDEO Demonstrates technique of glazing.

A complete restoration would remove all glass from the window, clean and prime the frame, reset the glass, and reglaze.

Hardware |

|

Hardware

Hardware may not work because it is clogged, needs oiling, or is broken.

How to Fix Casement Window Cranks provides guidance on getting cranks to work better.

How to Fix Casement Window Cranks provides guidance on getting cranks to work better.

Damaged or missing hardware can be replaced. There are numerous sources.

- H&R Window, Hazel Park, MI 248-544-8282

- Robert Brooke and Associates

- Blaine Window Hardware

A complete restoration would remove all hardware, clean (and polish if possible), oil, and repair or replace.

Sills & Casing |

|

Houses with steel windows usually have masonry window sills. If these are damaged, then there is a masonry problem, not a window problem.

If the sills happen to be wood, they may have deteriorated. Sills get the most exposure to weather and need the most routine maintenance or repair. The usual reason is that paint has not been maintained and has deteriorated, exposing the wood.

For information on repairing or replacing wood sills, see the section on "sills and casing" in our Historic Window Repair article.

Repainting |

|

Once windows will operate smoothly and are repaired, then the finish paint can be applied.

- Minimally, repaint all primed spots.

- Or repaint the entire window.

- Either way, apply two coats of finish paint (same brand as the primer in order to be chemically compatible.)

Major Repairs

When corrosion is extensive, or when metal window sections are misaligned, then major repair is required. Sometimes major repairs can be done with the windows in place. Other times, windows may have to be removed to a shop.

When corrosion is extensive, or when metal window sections are misaligned, then major repair is required. Sometimes major repairs can be done with the windows in place. Other times, windows may have to be removed to a shop.

Fortunately, major repairs rarely are needed for steel windows in houses. And severe deterioration is unlikely to happen for more than a few windows.

The scope of major repairs is presented in Preservation Brief 13 Steel Windows.

Generally a contractor with specialized knowledge and skills will be necessary for major repairs.

Weatherization of Steel Windows

What to Do for Weatherization

A good storm window is an essential.

- A storm window is the principal element for creating energy efficiency windows.

- Either exterior or interior storms work.

- An exterior storm also protects the window from weathering.

- An exterior storm also adds a layer of security on windows.

- Interior storms may offer a tighter seal on some steel casement windows. They can cover the entire window, which exterior storms may not do. This depends on window design.

For information on storm windows, see our article on storms.

Exterior caulking is needed everywhere around the window frames and sills.

Where siding meets the window sill and frame -- but not along the top, because that space lets any moisture from inside escape.

Where siding meets the window sill and frame -- but not along the top, because that space lets any moisture from inside escape. - Between storm windows and window frames - but leave some opening where the storm window rests on the sill, to let any moisture drain away.

For general instruction, see How to Caulk Metal

"Most small gaps up to 1/4 inch may use a 100 percent silicone caulking for metal, such as GE Silicone II Aluminum & Metal. Larger gaps should use a polyurethane caulk, such as SeamStitch Polyurethane Elastomeric Caulk."

Interior caulking is needed around interior window frames.

- The interior woodwork needs to be tight with the wall. If it is not, use spackling compound or caulk (paintable) to close the opening.

- Same where steel window frames meet the wall, where there is no woodwork.

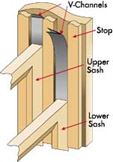

Interior weather stripping is needed where the operable portion of the sash fits into the fixed window frame. Removing excess paint will improve the fit.

- Vinyl V-strips in the channel where the sash closes. Easy to install, but short-lived.

- Compressible foam strips can be effective where there are larger gaps to fill. If space is tight, however, they may be too bulky to allow the window sash to close tightly.

- Metal weatherstripping that is designed specifically for steel casement windows are the best option for steel windows in good condition that require only a thin strip of insulation. Harder to do, but long-lived.

- The strips fasten to the inside channel of the fixed window frame with a built-in mounting clip.

- Strips usually are applied to the entire perimeter of the window opening, but for casement windows it may be best to avoid weatherstripping the hinge side. The natural wedging action of the weatherstripping on the three sides of the window often creates an adequate seal.

- To insure against galvanic corrosion between the bronze or brass weatherstripping and the steel window, the window must be painted prior to the installation of the metal weatherstripping.

- Sources for Metal Weatherstripping:

- Universal Weatherstrip and Building Supply.: A local source.

- Accurate Metal Weatherstrip Co.: Reported to be very knowledgeable and helpful by phone.

- Caulk mold works where there are substantial air infiltration gaps around the movable window, perhaps because the window is deformed. (This is not appropriate as a routing repair.)

- First, the fixed window frame must be thoroughly cleaned and any bare metal primed.

- Then a neat bead of firm setting caulk (low modulus), such as silicone, is applied to the fixed window frame, where the movable sash will touch. An example is Dow Corning C60 Premium Low Modulus External Silicone Sealant.

- A polyethylene tape (readily available) is then applied to the operable sash where it will contact the fixed frame.

- The window is then closed until the sealant has set (up to a month, see instructions).

- When the window is opened, the bead will have taken the shape of the air infiltration gap and the polyethylene tape can be removed.

Another option

"Several years ago I ran across a study showing that 1/4" laminated safety glass, with a .060 thick laminate in the middle, approaches the R-value and U-value of double paned glass with a 5/8" air gap. It also costs less than double paned glass, has 99% UV protection, is more sound resistant, is safer, and you never have to worry about failing seals between the panes of glass. All glass shops sell this and it costs less than double paned glass."

Contractors

There are reliable contractors who specialize in the window repair and restoration. They know how to do it correctly. Several well-known ones are listed below.

Since many of the repair and weatherization tasks are simple, general contractors, handymen, or house painters may be able to do them. However, employing non-specialized contractors for window repair can be risky.

Information About Working With Contractors

There are two reasons why employing non-specialized contractors for window repair can be risky.

- First, contractors sometime will say they can do something when they cannot. Then they do the wrong thing or do it badly. They want the business, of course.

- Second, contractors may advise you to do what they know how to do! And this may not be correct for you. If contractors do not know what the right thing is or how to do it, they often give contrary and bad advice.

Replacement window companies will advise you that your windows cannot be repaired and are energy inefficient. Their advice: buy their new windows!

Don't Believe It!

Advice. You need to know what work you need and how it should be done!

Here's how: study the DIY information. Even if you cannot DIY, it is the information that you need to understand what work you need contractors to do, and how they should do it.

- With this knowledge, you can talk intelligently with contractors.

- You can detect which ones know what is the right thing to do and how to do it right.

- And you can avoid the contractors who do not.

Contractors can learn! There are reliable contractors who just doesn't know about windows. They can learn what they need to know here in order to do good work.

Having a plan is very important here again. With a plan that prioritizes the work to be done, an owner can work with a contractor and get the most important work done first and within the budget. Also, if work must be spread out over time for financial reasons, the plan will help the owner and contractor set up the work in a series of affordable stages.

Disclaimer. The window repair and restoration contractors listed here have credentials for windows and have been recommended by building owners in Historic Districts. Neither the Historic Boston-Edison Association nor the Detroit Historic District Commission can guarantee your satisfaction with any contractor. Every owner must find contractors with whom they can work satisfactorily. Check their references yourself.

Turner Restoration | Building Hugger L3C |

H & R Window Repair Company | Sevonty Restoration LLC |